Xiaomeng • Harrier

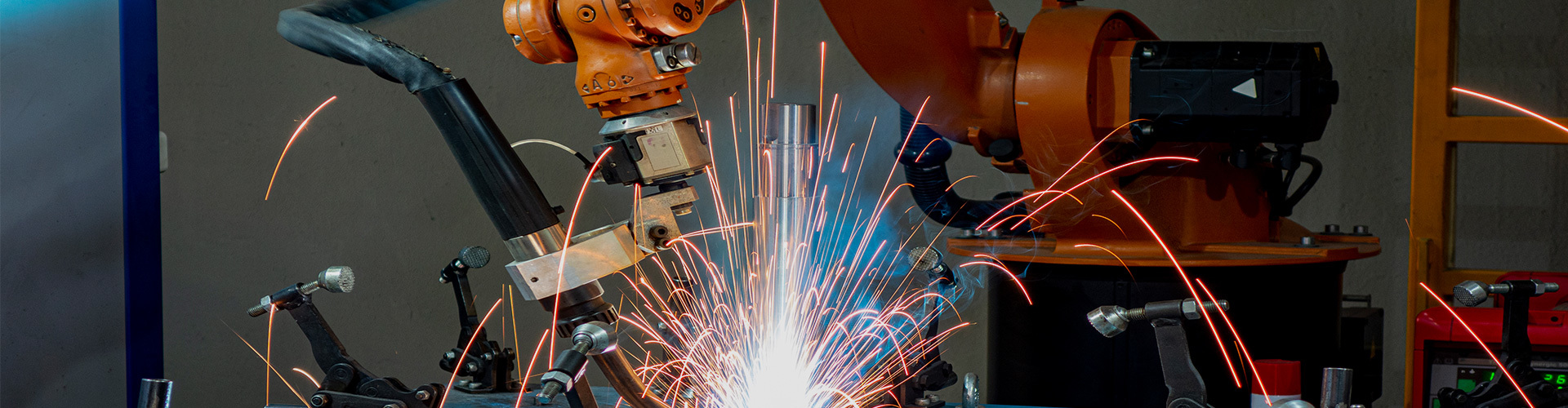

- Commodity name: Xiaomeng • Harrier

Product Details

Performance Parameter Introduction

| Name | Self-propelled All-Scene Large Piece Welding Robot (Xiao Meng - Yao I) |

| Model | WMM-10iD/8LHH500 |

| Net Weight | 1780KG |

| Dimensions | 2830*1605*1550mm |

| Minimum Turning Radius | 4800mm |

| Battery Parameters | 12V, 86Ah |

| Number of Batteries | 4 |

| Maximum Safe Driving Speed | 10km/h |

| Endurance Mileage | 19KM |

| Maximum Horizontal Welding Width | LT650-H3850mm LT: Distance from the front of the vehicle W: Horizontal welding width |

| Maximum Vertical Welding Height | LT915-V3725mm TT: Distance from the front of the vehicle H: Vertical welding height |

| System Power | 26.8KW |

| Repeat Positioning Accuracy | ±0.03mm |

| Welding Method | MIG Welding with Gas Protection |

| Welding Position | Horizontal Welding, Flat Welding, Vertical Welding, Overhead Welding |

| Welding Wire Specifications | Diameter φ0.8mm-φ1.6mm Wire |

| Robot Body | FANUCM-10iD/8L |

| Control Cabinet Model | R-30iB Mate Plus |

System Function Introduction

1. Equipped with walking function, can flexibly reach designated welding positions for welding work;

2. Real-time Monitoring System: Through independently developed imaging system, after welding, the mobile robot can check the welding quality of the weld seam at corresponding joints;

3. FANUC Robot Body M-10iD/8L with hollow rotating axis for built-in cables, providing stronger welding posture reachability;

4. Open control system, the control cabinet can communicate with most laser positioning systems on the market, enabling laser positioning and tracking functions for the welding system, making it easier to add welding auxiliary functions later (optional functions require opening corresponding ports);

5. Equipped with three arc welding functions: multi-layer multi-pass, arc tracking, and contact positioning;

6. The welding machine is a 500A industrial heavy-duty welding machine, optional water-cooled welding gun, with better adaptability in harsh welding environments;

7. RL Industrial Control Board: Capable of centralized collection and management of welding data, visualizing detailed information, collecting welding voltage and current, welding time, welding length, robotic arm coordinates, GPS positioning, etc., for data analysis. The generated data can also be transmitted to other applications via Modbus RTU protocol based on 485 communication.

Welding Method Introduction

| Welding Method | MIG Welding with Gas Protection |

| Workpiece Material | Carbon Steel/Stainless Steel |

| Welding Position | Horizontal Welding, Flat Welding, Vertical Welding, Overhead Welding |

| Welding Wire | Diameter Φ0.8-Φ1.6mm Solid Wire/Flux-Cored Wire (Coil Wire) |

| Welding Wire Extension Length | 10-20mm |

Introduction of advantages:

1、Self-walking function

The self-walking function can flexibly reach the designated welding station and reduce the turnover and handling of welding work.

2、Hydraulic positioning system

Hydraulic positioning ensures the stability of the robot and ensures the consistency of welding quality.

3、Lifting function

The lifting function expands the welding range, reduces the difficulty of welding, improves the efficiency of welding, and reduces the risk of operators.

4、Data cloud storage function

The data cloud storage function can store the current, voltage and welding time and length during welding.

5、Automatic gun cleaning function

One-stop gun cleaner can help us quickly complete the welding gun wire cutting, cleaning, oil injection and other operations, greatly improve the efficiency of work.

6、Mobile phone remote control function

The mobile phone remote control function can remotely detect the running status of the robot in the mobile phone APP.

7、Real-time monitoring function

Real-time monitoring system, can detect the welding process in real time, intelligent detection.

Key words:

Xiaomeng • Harrier

-

File size: 4.7MB

Related Products